Aircraft locking mechanism

Revolutionizing Aerospace Safety: The Impact of CNC Machining on Aircraft Locking Mechanisms

In the dynamic world of aerospace engineering, every component plays a vital role in ensuring the safety and functionality of an aircraft. Among these components, locking mechanisms are the guardians of safety, protecting critical access points and equipment during flight and ground operations. With the advent of computer numerical control (CNC) machining, the manufacturing of aircraft locking mechanisms underwent a major shift, ushering in a new era of precision, reliability, and innovation. This article delves into the far-reaching impact of CNC machining on the manufacturing of aircraft locking mechanisms, highlighting advancements that have revolutionized aerospace safety.

The Evolution of Aircraft Locking Mechanisms:

Aircraft locking mechanisms are the primary means of securing access panels, cargo doors, landing gear, and a variety of other components essential to flight operations. Traditionally, these mechanisms were crafted through manual machining processes that often resulted in inconsistencies and inefficiencies. However, with the introduction of CNC machining, aerospace engineers were given unprecedented control over the manufacturing process, enabling the production of locking mechanisms with unparalleled precision and reliability.

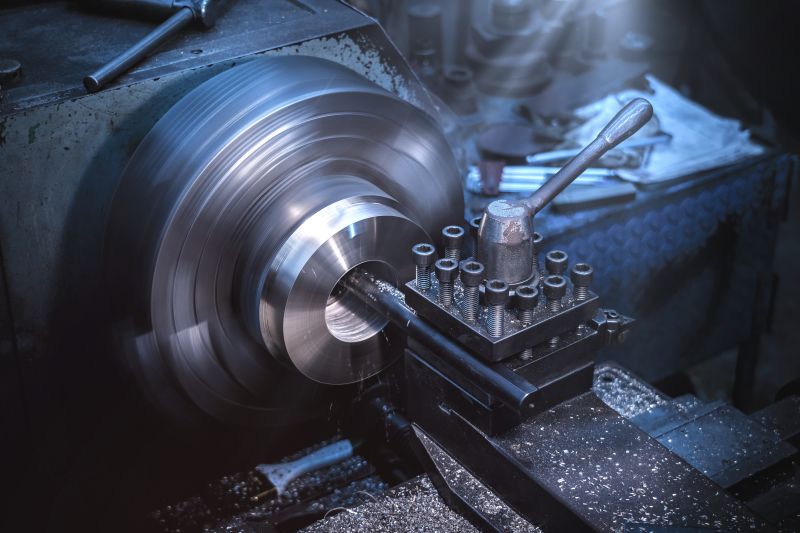

Precision Engineering:

Precision is critical in the aerospace industry, especially for critical components such as locking mechanisms. CNC machining offers exceptional precision, allowing manufacturers to produce complex geometries and tight tolerances with unmatched accuracy. Whether milling complex keyways, drilling precise mounting holes, or threading intricate locking mechanisms, CNC machines ensure that each component meets the precise specifications required for optimal performance and safety.

Complex Geometries and Materials:

Modern aircraft locking mechanisms often feature complex geometries and are made from high-strength materials such as titanium, stainless steel, and aluminum alloys. CNC machining excels at handling these challenges, capable of manufacturing components with complex shapes, internal cavities, and precise surface finishes. With multi-axis machining capabilities and advanced toolpath generation capabilities, CNC machines can easily mill, turn, and grind locking mechanisms to meet the stringent requirements of aerospace applications.

Enhanced Security Features:

In addition to precision engineering, CNC machining enables aerospace engineers to integrate advanced security features into aircraft locking mechanisms. Whether it’s biometric scanners, electronic locks, or tamper-proof designs, CNC machines have the flexibility to seamlessly incorporate cutting-edge technology. By leveraging the capabilities of CNC machining, manufacturers can enhance the safety of aircraft systems while ensuring ease of operation and maintenance for crew and ground personnel.

Quality Assurance and Reliability:

The reliability of aircraft locking mechanisms is critical to the safety of passengers, crew, and cargo. CNC machining plays a vital role in ensuring the quality and reliability of these components through a rigorous quality assurance process. By integrating advanced metrology equipment into CNC systems, manufacturers can perform real-time inspections and measurements to verify dimensional accuracy, surface finish, and material integrity. This proactive approach to quality control minimizes the risk of defects and ensures that each locking mechanism meets the rigorous standards of the aerospace industry.

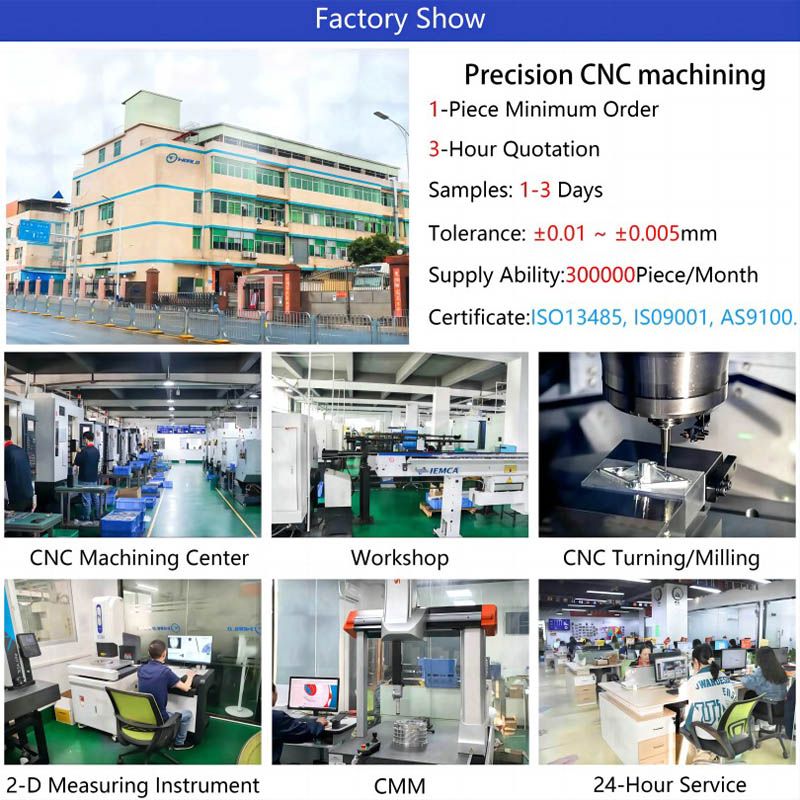

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.