Aircraft Struts Parts

Advances in CNC Machining Technology Transform the Manufacturing of Aircraft Strut Parts

In the complex world of aerospace engineering, precision and reliability are paramount. Aircraft struts are critical components that support the weight of the aircraft during landing and ground operations, and require the highest manufacturing standards. As technology has evolved, computer numerical control (CNC) machining has become a game-changer in the production of these critical parts. This article explores how CNC machining has revolutionized the manufacturing of aircraft strut parts, improving aviation performance, safety, and efficiency.

Role of CNC Machining in Aerospace:

CNC machining has long been an integral part of aerospace manufacturing, providing unparalleled precision and repeatability. In the production of aircraft strut parts, tight tolerances and complex geometries are the norm, and CNC machining ensures consistency and quality at every stage of production. By translating digital designs into physical components with extreme accuracy, CNC machines enable aerospace engineers to manufacture struts that meet stringent safety and performance standards.

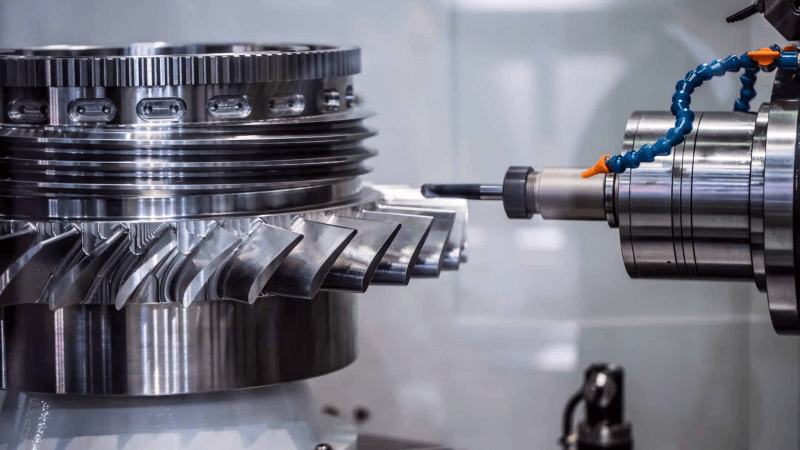

Precision Engineering:

Aircraft strut components, such as landing gear assemblies and hydraulic cylinders, require complex machining to achieve the required specifications. CNC machining excels in this area, accurately forming and finishing metal alloys commonly used in aerospace applications. Whether milling, turning or grinding, CNC machines deliver sub-micron accuracy, ensuring each part meets the exact requirements of the design.

Complex Geometries:

Modern aircraft struts are designed to withstand tremendous forces while minimizing weight and maximizing structural integrity. This often requires manufacturing components with complex geometries, such as curved surfaces, tapered profiles and internal cavities. CNC machining capabilities, including multi-axis machining and advanced toolpath generation, enable manufacturers to easily produce these complex parts. By leveraging the power of CAD/CAM software, engineers can optimize designs for improved manufacturability and streamline production processes.

Material Flexibility:

Aircraft strut components are often made from high-strength materials such as aluminum, titanium and stainless steel to withstand the rigors of flight conditions. CNC machining offers unparalleled versatility in machining these alloys, allowing for precise cutting, drilling and forming without compromising material properties. Whether it’s a bulkhead, trunnion or piston rod, CNC machines can easily handle a wide range of materials, ensuring each component meets the rigorous standards of the aerospace industry.

Quality Assurance:

In aerospace manufacturing, quality control is non-negotiable. Aircraft reliability and safety depend on the integrity of every component, including strut components. CNC machining plays a vital role in ensuring quality assurance by enabling real-time monitoring and inspection of machined components. With advanced metrology equipment integrated into CNC systems, manufacturers can verify dimensional accuracy, surface finish, and material integrity throughout the production process, minimizing the risk of defects and ensuring compliance with regulatory standards.

Efficiency and Cost-Effectiveness:

While maintaining uncompromising quality standards, CNC machining also offers significant advantages in terms of efficiency and cost-effectiveness. By automating repetitive tasks and optimizing machining parameters, manufacturers can streamline production workflows and reduce lead times. In addition, the scalability of CNC machining allows for efficient production of both small and large batches of aircraft strut components, providing flexibility to meet the dynamic needs of the aerospace industry. In the long run, this means lower production costs and enhanced competitiveness for aerospace manufacturers.

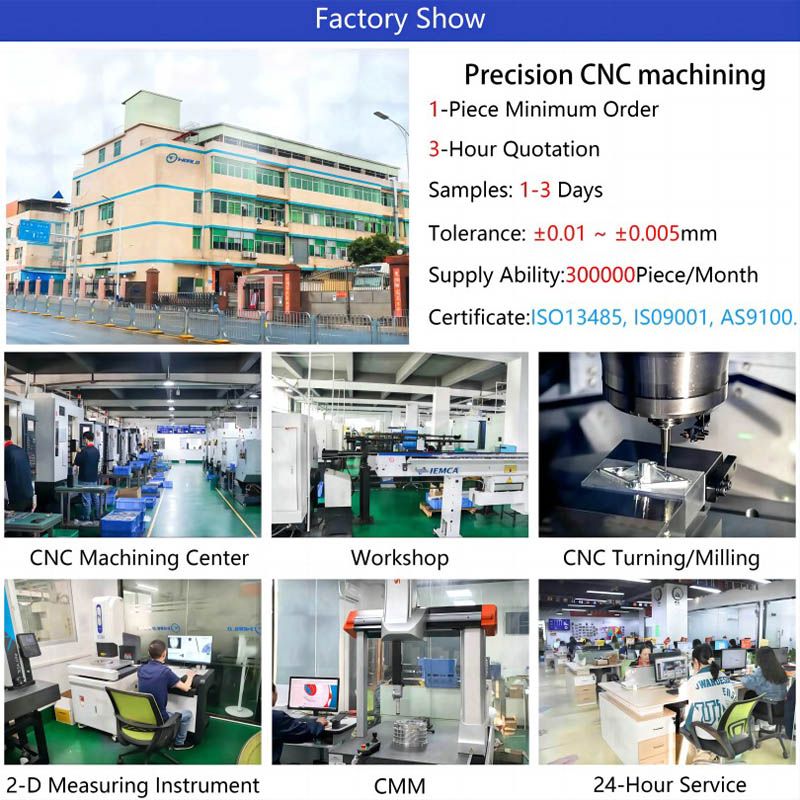

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.