CNC machining services custom wheel parts

Every component, from the engine to the exterior, contributes to the overall aesthetic and performance of a vehicle. Among these components, wheels stand out as a focal point, not only for their functional importance but also for their ability to enhance the vehicle's appearance. Custom wheel parts, crafted with precision and care, have become a hallmark of automotive enthusiasts seeking to personalize their rides. In this essay, we explore the indispensable role of CNC machining services in the creation of these bespoke wheel components.

CNC (Computer Numerical Control) machining has revolutionized the manufacturing process, offering unparalleled precision, efficiency, and versatility. In the realm of custom wheel parts, CNC machining services play a pivotal role in translating design concepts into tangible components that meet the exact specifications and requirements of automotive enthusiasts.

One of the primary advantages of CNC machining in crafting custom wheel parts is its ability to work with a wide range of materials, including aluminum, steel, titanium, and even composite materials. This versatility allows for the creation of lightweight yet durable wheel components that offer superior performance and aesthetics. Whether it's intricate spoke designs, unique rim profiles, or personalized center caps, CNC machining can precisely shape and refine these components to perfection.

Moreover, CNC machining enables the production of custom wheel parts with exceptional dimensional accuracy and surface finish. Each component is meticulously programmed and machined to ensure consistency and uniformity, resulting in wheel assemblies that not only look stunning but also perform flawlessly on the road. Whether it's achieving tight tolerances for wheel hub bearings or creating intricate patterns on the wheel face, CNC machining allows for precise control over every aspect of the manufacturing process.

In addition to precision and accuracy, CNC machining services offer flexibility and scalability, making it ideal for both prototyping and production runs of custom wheel parts. Automotive enthusiasts can collaborate with skilled machinists and engineers to bring their design ideas to life, iterating and refining prototypes until they achieve the desired outcome. Once the design is finalized, CNC machining facilities can seamlessly transition to mass production, ensuring consistent quality and timely delivery of custom wheel parts to meet market demand.

Furthermore, CNC machining services enable customization beyond just aesthetics. With advanced CAD (Computer-Aided Design) software and simulation tools, designers can optimize the structural integrity and performance of custom wheel parts, taking into account factors such as weight distribution, aerodynamics, and thermal management. This holistic approach ensures that each wheel component not only looks impressive but also enhances the overall driving experience.

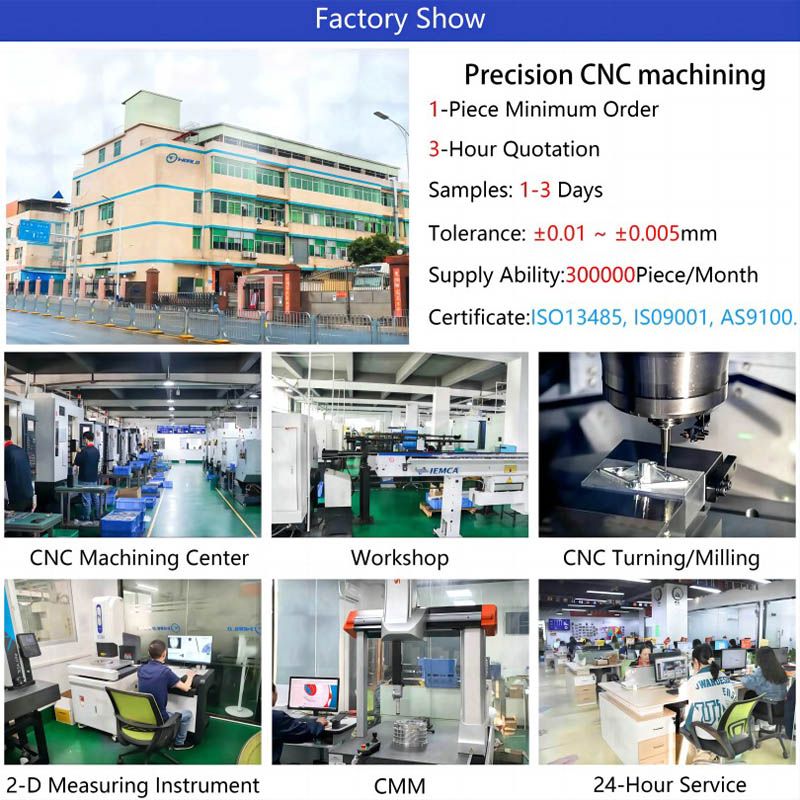

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.