CTH12 Ball Screw 16mm Stroke Automatic System Manual Linear Module Slide rail linear guide

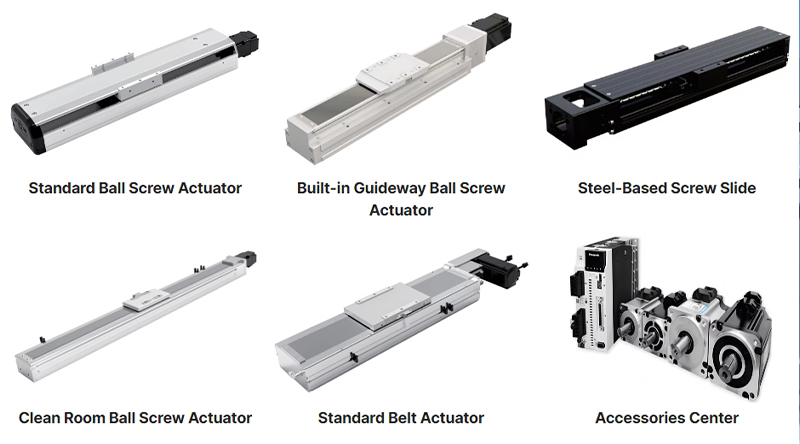

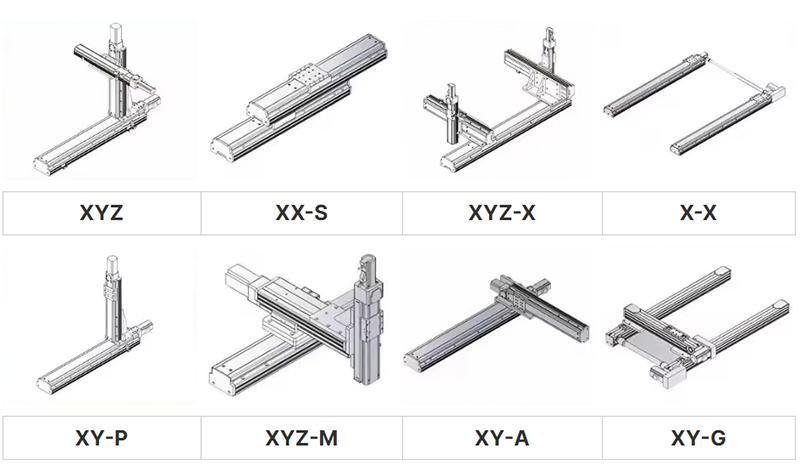

CTH12 Linear Module lies a sophisticated ball screw mechanism, meticulously engineered to deliver unparalleled precision and accuracy in linear motion control. With a stroke length of 16mm, this module offers precise positioning capabilities, catering to the diverse needs of industrial applications. Whether integrated into automated systems or utilized in manual machining setups, the CTH12 Linear Module ensures smooth and consistent motion, empowering manufacturers to achieve optimal results with every operation.

Key Features and Advantages

Ball Screw Technology: The incorporation of a ball screw mechanism enables the CTH12 Linear Module to translate rotary motion into precise linear movement with minimal friction and backlash. This technology ensures high accuracy and repeatability, making it ideal for tasks that demand meticulous precision, such as CNC machining and robotic assembly.

Versatile Stroke Length: With a stroke length of 16mm, the CTH12 Linear Module offers versatility in motion control, accommodating a wide range of applications across various industries. Whether performing micro-machining operations or handling larger workpieces, this module adapts seamlessly to diverse manufacturing requirements.

Automatic and Manual Operation Modes: The CTH12 Linear Module is equipped with both automatic and manual operation modes, providing flexibility in usage. In automated systems, it integrates seamlessly with control systems for precise, hands-free operation. Conversely, in manual machining setups, it offers intuitive control for operators, allowing for fine adjustments and customization as needed.

Slide Rail Linear Guide: The inclusion of a slide rail linear guide ensures stability and smooth motion, even under dynamic operating conditions. This feature enhances the overall performance of the CTH12 Linear Module, minimizing vibrations and deflections that could compromise machining accuracy and surface finish quality.

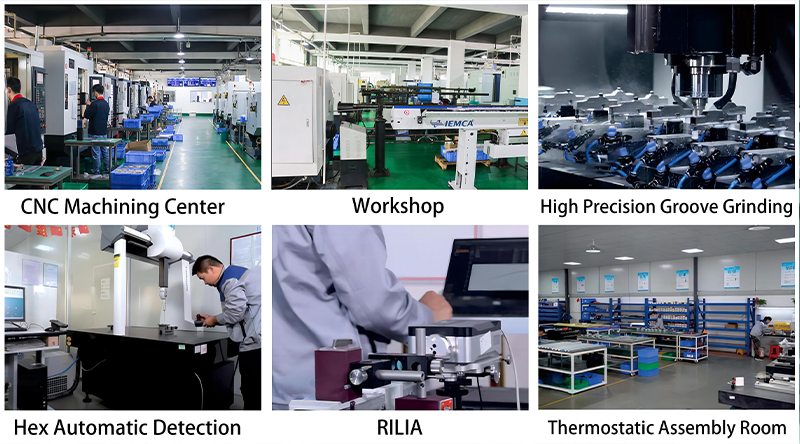

Reliability and Durability: Constructed from high-quality materials and subjected to rigorous testing, the CTH12 Linear Module exemplifies reliability and durability. Its robust design ensures long-term performance and minimal maintenance requirements, contributing to enhanced productivity and cost-effectiveness for manufacturers.

Applications Across Industries

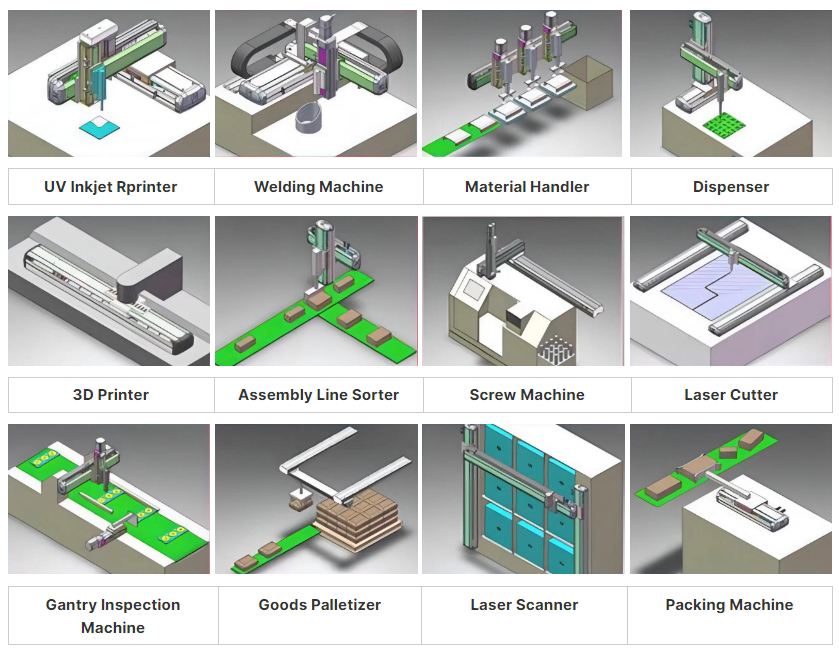

The versatility and precision of the CTH12 Linear Module make it indispensable across a broad spectrum of industries:

Automotive Manufacturing: In automotive production lines, the CTH12 facilitates precise positioning and movement control, enabling the machining of critical components with tight tolerances and complex geometries.

Electronics Assembly: In the electronics industry, where miniaturization and precision are paramount, the CTH12 ensures accurate placement of components during circuit board assembly and semiconductor packaging processes.

Medical Device Production: In medical device manufacturing, the CTH12 plays a crucial role in machining implants, surgical instruments, and diagnostic equipment with exceptional precision and reliability.

Q:How long does customization take?

A: Customization of linear guideways requires determining the size and specifications based on the requirements, which typically takes around 1-2 weeks for production and delivery after placing the order.

Q. What technical parameters and requirements should be provided?

Ar: We require buyers to provide the three-dimensional dimensions of the guideway such as length, width, and height, along with load capacity and other relevant details to ensure accurate customization.

Q. Can free samples be provided?

A: Usually, we can provide samples at the buyer's expense for the sample fee and shipping fee, which will be refunded upon placing the order in the future.

Q. Can on-site installation and debugging be performed?

A: If a buyer requires on-site installation and debugging, additional fees will apply, and arrangements need to be discussed between the buyer and the seller.

Q. About price

A: We determine the price according to the specific requirements and customization fees of the order, please contact our customer service for specific pricing after confirming the order.