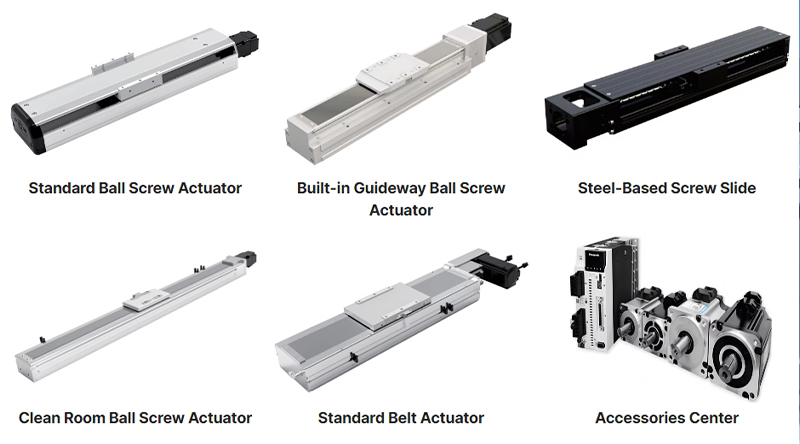

CTH4 Single Axis Built in Guideway Ball Screw Actuator Linear Module

Introduction to CTH4 Linear Module

The CTH4 Linear Module represents a fusion of cutting-edge technology and engineering prowess. At its core lies a ball screw actuator, a fundamental component renowned for its accuracy and reliability in translating rotary motion into linear motion. What sets the CTH4 apart is its integration of a built-in guideway, streamlining the assembly process and optimizing space utilization within machinery.

Key Features and Benefits

Precision and Accuracy: The incorporation of a ball screw mechanism ensures precise positioning and movement control, crucial for tasks requiring high accuracy and repeatability. Whether in manufacturing, robotics, or semiconductor industries, this level of precision is indispensable for achieving optimal performance.

Compact Design: By integrating the guideway directly into the module, the CTH4 minimizes the footprint required for installation. This compact design not only saves valuable space but also enhances overall system efficiency by reducing unnecessary bulk and weight.

High Load Capacity: Despite its streamlined profile, the CTH4 Linear Module boasts impressive load-bearing capabilities. Whether handling heavy payloads or enduring constant dynamic forces, this module excels in maintaining stability and reliability under demanding operational conditions.

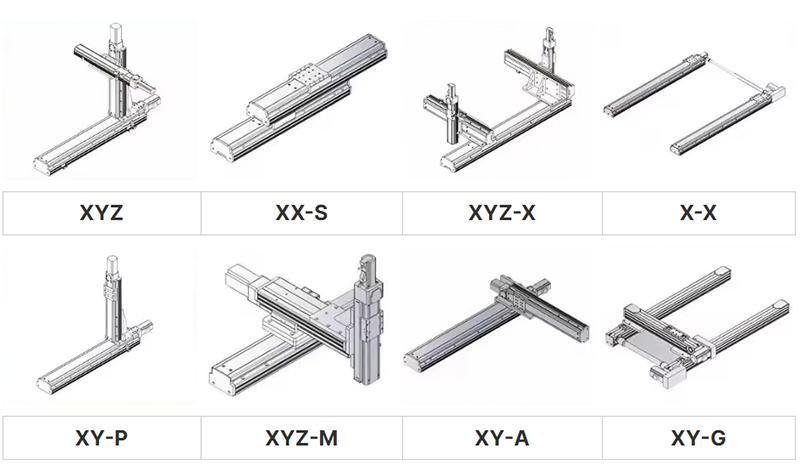

Versatility: From simple linear motion applications to complex automated systems, the CTH4 accommodates a wide range of tasks with ease. Its adaptable design makes it suitable for diverse industrial settings, offering flexibility in configuration and integration.

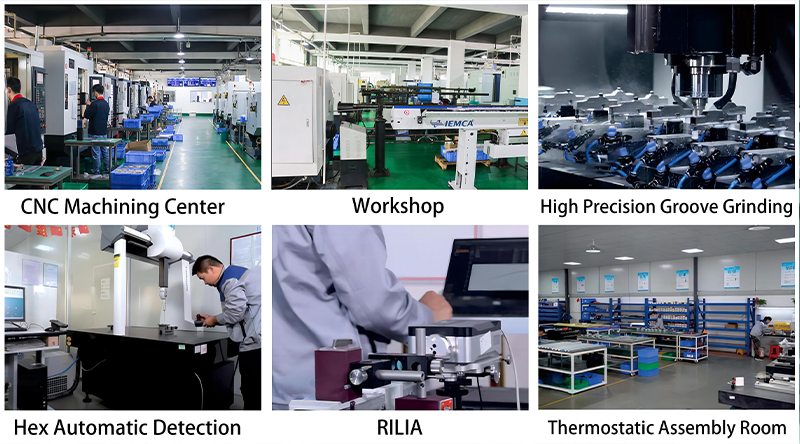

Durability and Longevity: Constructed from high-quality materials and subjected to rigorous testing protocols, the CTH4 Linear Module exhibits exceptional durability and longevity. This reliability translates into reduced downtime and maintenance costs, ensuring uninterrupted productivity for extended periods.

Applications Across Industries

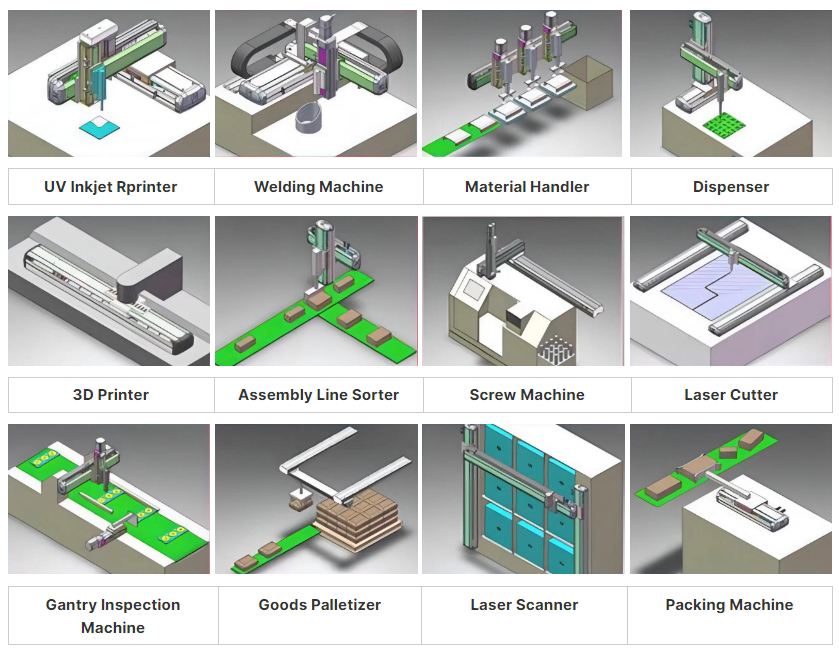

The versatility and performance of the CTH4 Linear Module make it indispensable across various industrial sectors:

Manufacturing: In automated production lines, the CTH4 facilitates precise material handling, assembly, and inspection processes, optimizing efficiency and throughput.

Robotics: Integrated into robotic arms and gantry systems, the CTH4 enables agile and accurate movement, enhancing the performance of robotic applications in industries ranging from automotive manufacturing to logistics.

Semiconductor: In semiconductor fabrication equipment, where nanometer-scale precision is paramount, the CTH4 ensures the smooth operation of wafer handling and lithography systems, contributing to the production of advanced microelectronics.

Future Prospects and Innovations

As technology continues to advance, the CTH4 Linear Module is poised to evolve further, incorporating features such as enhanced connectivity, predictive maintenance capabilities, and intelligent control systems. These innovations will not only augment its performance but also enable seamless integration into the emerging paradigm of Industry 4.0.

Q:How long does customization take?

A: Customization of linear guideways requires determining the size and specifications based on the requirements, which typically takes around 1-2 weeks for production and delivery after placing the order.

Q. What technical parameters and requirements should be provided?

Ar: We require buyers to provide the three-dimensional dimensions of the guideway such as length, width, and height, along with load capacity and other relevant details to ensure accurate customization.

Q. Can free samples be provided?

A: Usually, we can provide samples at the buyer's expense for the sample fee and shipping fee, which will be refunded upon placing the order in the future.

Q. Can on-site installation and debugging be performed?

A: If a buyer requires on-site installation and debugging, additional fees will apply, and arrangements need to be discussed between the buyer and the seller.

Q. About price

A: We determine the price according to the specific requirements and customization fees of the order, please contact our customer service for specific pricing after confirming the order.