CTH5 50-800mm Precise CNC Module Slide Embedded dust-free linear module screw slide table

CTH5 CNC Module Slide represents a harmonious integration of advanced engineering principles and state-of-the-art materials. Designed to cater to the exacting demands of CNC machining, this module slide embodies precision in every aspect of its construction and operation. The incorporation of dust-free linear module screw technology signifies a departure from traditional sliding mechanisms, heralding a new era of cleanliness and efficiency in manufacturing environments.

Key Features and Advantages

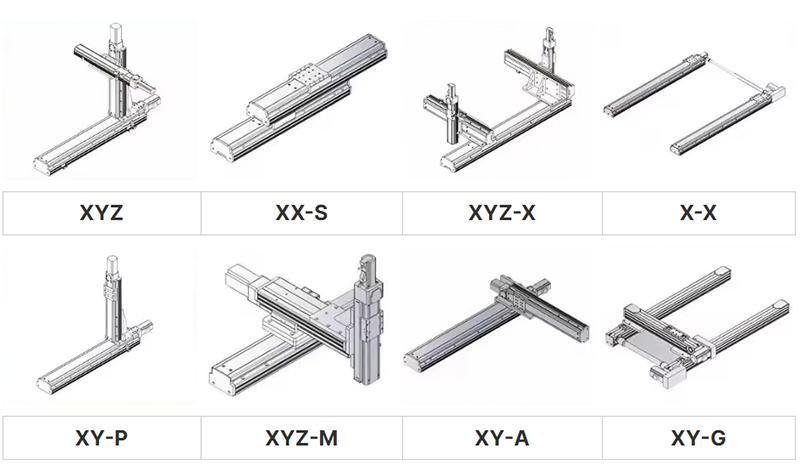

Unparalleled Precision: The CTH5 CNC Module Slide excels in delivering micron-level precision, ensuring that every movement is executed with utmost accuracy. Whether traversing across the X, Y, or Z axes, this module slide maintains tight tolerances, thereby enabling the production of intricate components and assemblies with minimal deviation from design specifications.

Versatile Range: With a configurable length spanning from 50mm to 800mm, the CTH5 accommodates a diverse array of machining applications. From small-scale prototyping to large-scale production runs, this module slide offers scalability and adaptability, catering to the evolving needs of manufacturers across various industries.

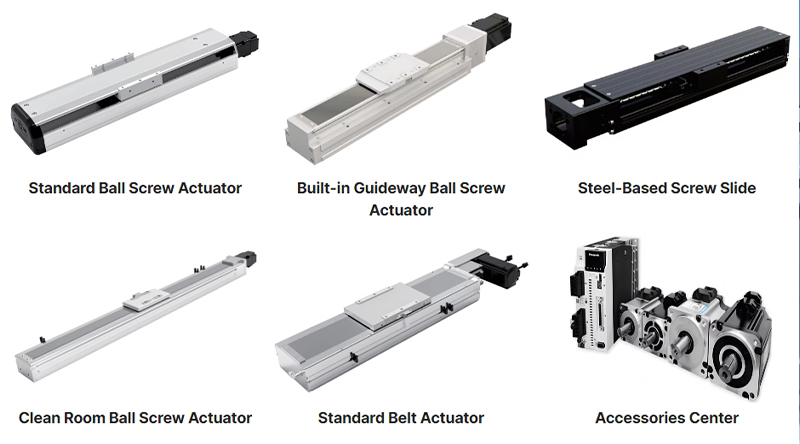

Embedded Dust-Free Linear Module Screw: By integrating a dust-free linear module screw into its design, the CTH5 ensures a clean and contamination-free operating environment. This feature is particularly crucial in precision machining, where even the slightest impurities can compromise the integrity of machined components and impair equipment performance.

Enhanced Stability and Rigidity: Engineered for robustness, the CTH5 CNC Module Slide exhibits exceptional stability and rigidity under dynamic machining conditions. Whether subjected to high-speed cutting or heavy-duty milling operations, this slide table maintains optimal performance, minimizing vibrations and deflections that could compromise machining accuracy.

Efficient Lubrication System: The inclusion of an efficient lubrication system prolongs the service life of the CTH5 CNC Module Slide, ensuring smooth and reliable operation over extended periods. This feature not only reduces maintenance requirements but also enhances overall productivity by minimizing downtime associated with component wear and tear.

Applications in Precision Manufacturing

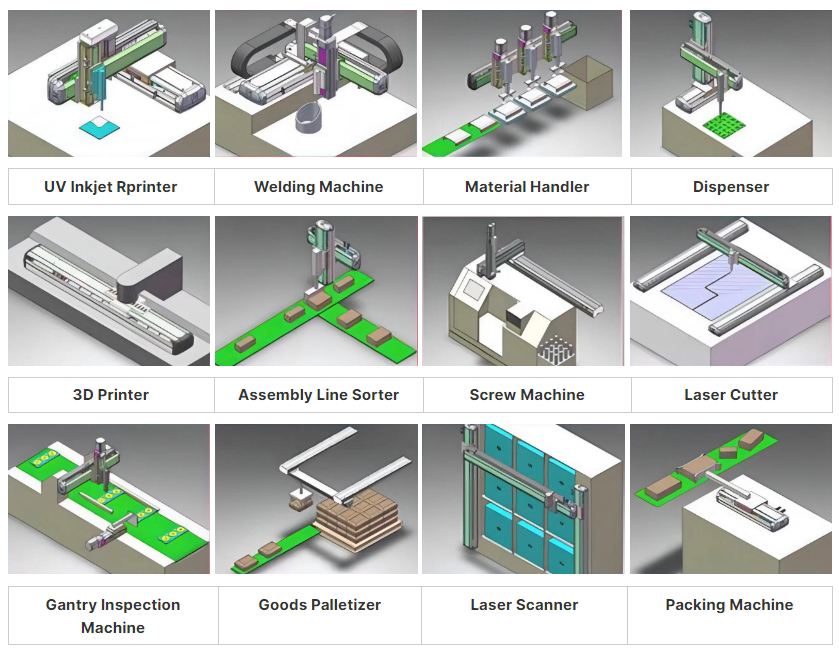

The versatility and precision of the CTH5 CNC Module Slide make it indispensable across a wide spectrum of manufacturing applications:

Automotive Industry: From precision machining of engine components to mold making for vehicle body panels, the CTH5 facilitates the production of high-quality automotive parts with unparalleled accuracy.

Aerospace Sector: In aerospace manufacturing, where stringent quality standards and tight tolerances are paramount, the CTH5 plays a crucial role in machining critical components for aircraft engines, airframes, and avionics systems.

Medical Device Manufacturing: In the production of medical implants, surgical instruments, and diagnostic equipment, the CTH5 enables manufacturers to achieve the intricate geometries and surface finishes required for optimal performance and biocompatibility.

Q:How long does customization take?

A: Customization of linear guideways requires determining the size and specifications based on the requirements, which typically takes around 1-2 weeks for production and delivery after placing the order.

Q. What technical parameters and requirements should be provided?

Ar: We require buyers to provide the three-dimensional dimensions of the guideway such as length, width, and height, along with load capacity and other relevant details to ensure accurate customization.

Q. Can free samples be provided?

A: Usually, we can provide samples at the buyer's expense for the sample fee and shipping fee, which will be refunded upon placing the order in the future.

Q. Can on-site installation and debugging be performed?

A: If a buyer requires on-site installation and debugging, additional fees will apply, and arrangements need to be discussed between the buyer and the seller.

Q. About price

A: We determine the price according to the specific requirements and customization fees of the order, please contact our customer service for specific pricing after confirming the order.