Customized Metal Milling, Cutting, and Polishing Services

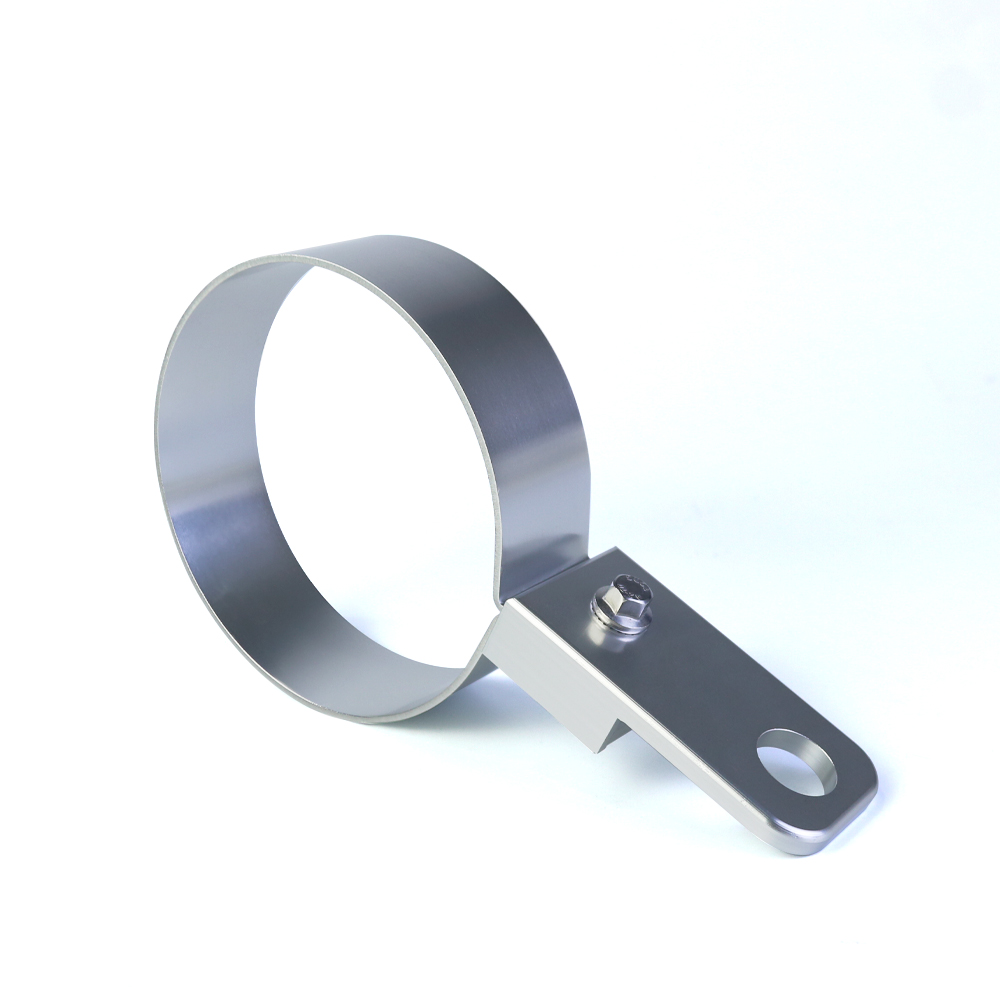

Product Overview

When it comes to manufacturing metal components, precision and quality are crucial. Whether you're in the automotive, aerospace, electronics, or industrial sector, having the right parts tailored to your exact specifications can significantly enhance your product’s performance. That's where customized metal milling, cutting, and polishing services come into play. These processes offer a comprehensive solution for producing high-quality, precision-engineered parts that meet the unique needs of your project.

What Are Customized Metal Milling, Cutting, and Polishing?

1.Metal Milling

Milling is a machining process that involves using rotating cutting tools to remove material from a workpiece. This allows us to create parts with complex shapes, precise dimensions, and smooth surfaces. Custom metal milling is essential for producing parts with unique designs and specifications, whether you're working with steel, aluminum, brass, copper, or other metals.

•Precision milling is perfect for producing gears, brackets, housings, and other parts requiring high tolerance levels.

2.Metal Cutting

Cutting is a versatile process that allows us to shape and size metals according to your exact specifications. This can be achieved through a variety of methods, such as laser cutting, plasma cutting, water jet cutting, and shearing. Depending on the material and design requirements, we choose the most efficient cutting method to achieve clean, accurate results.

•Customized metal cutting ensures that each part fits your design, whether it's a simple cut or a more intricate shape.

3.Metal Polishing

Polishing is the final touch in the process of customizing metal parts. This service is crucial for improving the aesthetic appeal of the part while also enhancing its surface finish. Polishing can smooth rough surfaces, eliminate burrs, and provide a sleek, shiny finish to metal components.

•Customized metal polishing ensures that your parts not only perform well but also have the high-quality appearance required for products used in consumer-facing applications, such as luxury items, decorative components, and medical devices.

Why Choose Customized Metal Milling, Cutting, and Polishing?

•High Precision and Accuracy

The combination of advanced machinery and expert technicians allows us to produce metal parts with extremely tight tolerances. Whether it’s milling or cutting, our services guarantee the utmost accuracy in dimensions, ensuring that your parts fit perfectly into your assembly or machine.

•Tailored Solutions for Unique Requirements

Every project has unique needs, and our customized metal services are designed to meet those specific requirements. Whether you're designing parts for high-performance machinery, complex mechanical systems, or luxury consumer products, we offer flexible, tailored solutions. From intricate designs to custom sizes, we provide the right services to create the perfect components.

•Multiple Metalworking Techniques Under One Roof

By offering milling, cutting, and polishing in-house, we streamline the production process and reduce the need for outsourcing. This not only ensures faster turnaround times but also allows for greater control over quality at every stage of production. Whether you're producing prototypes or large runs, we have the capabilities to handle all your metalworking needs.

•Versatile Material Selection

We work with a wide range of metals, including stainless steel, aluminum, brass, copper, and titanium. Whether you need parts for high-strength applications or corrosion-resistant components, we can select the best material for your specific needs.

•High-Quality Surface Finishes

The polishing process not only enhances the aesthetic quality of your parts but also improves corrosion resistance, smoothness, and wear resistance. We offer a variety of polishing techniques to match your desired finish, from mirror finishes to satin or matte finishes.

•Cost-Effective Production

Customized metal milling, cutting, and polishing services can be more cost-effective than traditional manufacturing methods, especially when you’re looking for high-volume production or one-off custom parts. We optimize the manufacturing process to reduce waste and minimize costs while still maintaining high standards of quality and precision.

Key Applications of Customized Metal Milling, Cutting, and Polishing

•Automotive Parts

From engine components to custom brackets and housings, metal milling and cutting services are essential in the production of automotive parts. Our services help produce high-precision automotive components that fit perfectly and perform under demanding conditions. We also offer polishing for parts that require a smooth finish for both aesthetic and functional reasons, such as exhaust tips or decorative trim pieces.

•Aerospace and Aviation

The aerospace industry demands components that are both lightweight and highly durable. Using milling, cutting, and polishing, we manufacture aerospace parts like aircraft brackets, landing gear components, and engine parts with exacting standards. Our polishing services ensure that critical parts maintain their smooth finish for improved airflow and reduced friction.

•Electronics and Electrical Components

Precision is essential when producing electronics components such as connectors, heat sinks, and circuit board housings. Through customized milling and cutting, we manufacture parts to tight tolerances that fit perfectly within your devices. The polishing process enhances surface conductivity and aesthetics, particularly in consumer-facing products.

•Medical and Dental Devices

The medical and dental industries require parts that are both biocompatible and highly precise. Milled and cut metal components are used in devices like implants, surgical instruments, and dental crowns. Our polishing services help ensure these parts are smooth, free from burrs, and safe for medical use.

•Industrial Equipment and Machinery

From machinery housings to gears and shafts, we provide customized milling, cutting, and polishing for a wide variety of industrial parts. Our services help produce parts that endure extreme pressure and high levels of wear while maintaining peak performance.

•Decorative and Luxury Items

For items requiring a high-end finish, such as luxury watches, jewelry, or high-end consumer products, metal polishing is crucial. We provide customized services to achieve the perfect finish for these parts, ensuring they stand out with a flawless, high-quality appearance.

If you're looking for high-quality, customized metal milling, cutting, and polishing services, look no further. We specialize in providing precision-engineered components for a variety of industries, ensuring that your parts meet the highest standards for performance, appearance, and durability.

Q1:What Types of Metals Can Be Processed Using These Services?

A1:These services are suitable for a wide range of metals, including: Aluminum Steel (including stainless steel and carbon steel) Brass Copper Titanium Nickel Alloys Magnesium Precious Metals (gold, silver, etc.) Whether you're working with soft metals like aluminum or tougher alloys like titanium, customized metal services can handle various material types to meet your design and performance needs.

Q2:How Do You Ensure Quality in Customized Metal Services?

A2:To ensure high-quality results, a professional service provider typically follows these practices: Advanced Machinery: Using state-of-the-art CNC (Computer Numerical Control) milling machines, laser cutters, and polishing equipment for precision and consistency. Rigorous Testing: Conducting quality control checks throughout the manufacturing process to verify tolerances, dimensions, and finishes. Experienced Technicians: Skilled professionals ensure that each part meets your specifications and industry standards. Material Inspections: Ensuring that the metal used is of the highest quality, with appropriate alloy compositions for strength, corrosion resistance, and functionality.

Q3:How Long Does the Process Take?

A3:Part Complexity: More intricate designs will take longer to mill or cut. Quantity: Larger orders typically require more time, but batch production can improve efficiency. Materials: Some metals are easier to work with than others, affecting production time. Finishing: Polishing can add additional time to the process, depending on the level of finish required. Generally, the time can range from a few days for simpler jobs to several weeks for large, complex, or high-precision orders.

Q4:Can You Handle Custom Orders and Prototypes?

A4:Yes, customized metal services are ideal for both small-batch production and prototyping. Whether you need one-off prototypes or are preparing for mass production, these services can accommodate your specific needs. Working closely with a manufacturer ensures that your prototypes meet design expectations and are ready for testing and further refinement.

Q5:Can You Handle Large-Scale Production Runs?

A5:Yes, customized metal services can handle both small-scale custom projects and large-scale production runs. If you're planning mass production, a skilled service provider will optimize the manufacturing process for efficiency while maintaining quality and precision.