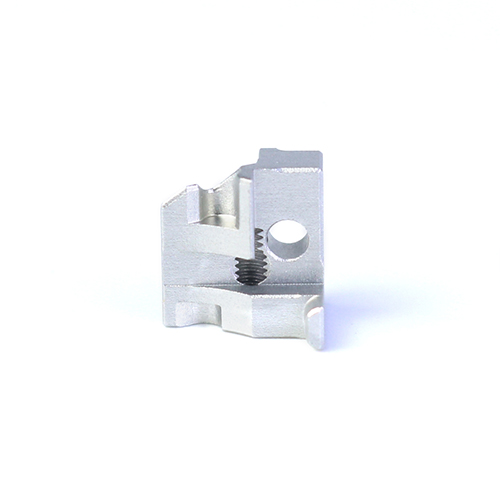

High-quality custom precision milled parts

Product Overview

In the world of manufacturing, precision CNC milling parts service plays a pivotal role in delivering high-quality, custom-made components for diverse industries. Whether you’re in the aerospace, automotive, electronics, or medical sector, CNC milling ensures unparalleled accuracy, efficiency, and flexibility for your projects.

Discover why our precision CNC milling parts service is the top choice for clients seeking excellence in machining and how we can bring your ideas to life with precision-crafted parts.

What Is Precision CNC Milling?

CNC milling (Computer Numerical Control milling) is a subtractive manufacturing process where rotary cutting tools remove material from a workpiece to create precise shapes and features. Unlike conventional methods, CNC milling offers exceptional accuracy, repeatability, and the ability to handle intricate geometries.

Our precision CNC milling service specializes in creating parts with tight tolerances, complex designs, and a wide range of materials, ensuring your specific requirements are met with unmatched quality.

Advantages of Our Precision CNC Milling Parts Service

1.Unrivaled Accuracy

Our state-of-the-art CNC milling machines deliver parts with tolerances as tight as ±0.01mm, ensuring precision for even the most complex designs.

2.Wide Material Selection

We mill a variety of materials, including aluminum, stainless steel, titanium, brass, plastics, and more. Each material is carefully selected based on your project’s specifications.

3.Complex Geometries

From simple flat surfaces to intricate 3D shapes, our CNC milling capabilities can handle even the most challenging designs with ease.

4.Cost-Effective Solutions

By utilizing advanced technology, we optimize the manufacturing process to minimize waste and reduce production costs without compromising quality.

5.Custom Finishes

Enhance the durability and aesthetics of your parts with finishes like anodizing, polishing, powder coating, or sandblasting.

6.Quick Turnaround Times

Our efficient production processes ensure that your parts are delivered on time, every time, whether for prototyping or large-scale production.

Applications of Precision CNC Milling Parts

Our CNC milling services cater to a wide range of industries and applications, including:

1.Aerospace Components

Lightweight yet robust parts such as brackets, housings, and structural elements.

2.Automotive Parts

Custom parts like engine components, transmission parts, and suspension systems.

3.Medical Devices

High-precision surgical instruments, implantable devices, and diagnostic equipment.

4.Electronics

Custom enclosures, heat sinks, and connectors for electronic devices.

5.Industrial Equipment

Precision-milled parts like gears, clamps, and mounting brackets.

6.Robotics

Components for robotic arms, precision joints, and automation systems.

How Our Process Works

1.Consultation & Design Review

Share your design files or specifications with us. Our engineers will review them for manufacturability and suggest optimizations if needed.

2.Material Selection

Choose from a variety of materials suited to your application. We provide expert recommendations to ensure the best results.

3.Precision Milling

Our CNC machines begin the manufacturing process, delivering parts with exceptional accuracy and consistency.

4.Surface Finishing

Customize your parts with finishes that enhance durability, appearance, and functionality.

5.Quality Inspection

Every part is meticulously inspected for dimensional accuracy, material quality, and surface finish.

6.Shipping

Once approved, your parts are securely packaged and shipped to your location.

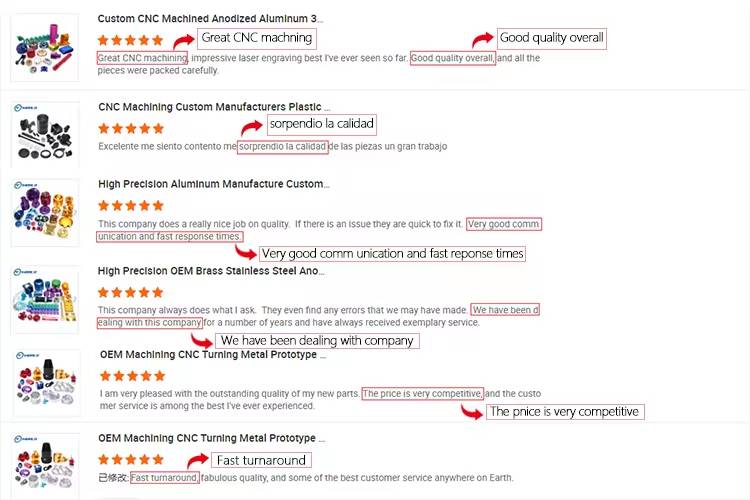

Partner with Us for Your CNC Milling Needs

When it comes to precision CNC milling parts service, our commitment to excellence sets us apart. With a focus on quality, efficiency, and customer satisfaction, we deliver parts that not only meet but exceed your expectations.

Q:What customization options are available for precision milled parts?

A:We offer fully customizable solutions, including:

Material selection: Wide range of metals and plastics.

Complex geometries: Capable of producing intricate designs.

Tolerances: Achieving tight tolerances of ±0.01mm or better.

Surface finishes: Options like anodizing, plating, polishing, and sandblasting.

Special features: Threads, slots, grooves, or multi-surface machining.

Q:What materials can you work with for custom milled parts?

A:We work with a variety of materials to meet specific application needs, including:

Metals: Aluminum, stainless steel, titanium, brass, copper, and alloy steels.

Plastics: ABS, polycarbonate, POM (Delrin), nylon, and more.

Specialty materials: Magnesium, Inconel, and other high-performance alloys.

Q:What is the maximum size of parts you can mill?

A:We can mill parts with dimensions up to 1,000mm x 500mm x 500mm, depending on the material and design requirements.

Q:Can you create prototypes before mass production?

A:Yes, we offer rapid prototyping services to ensure the design meets all functional and aesthetic requirements before full-scale production.

Q:What is your typical production timeline?

A:Our production timelines depend on complexity and order volume:

Prototyping: 5-10 business days

Mass production: 2-4 weeks

Q:Are your milled parts eco-friendly?

A:We are committed to sustainability and offer:

Eco-friendly materials

Waste-minimizing production techniques

Recycling programs for metal scrap

Q:What surface finishes can you provide for milled parts?

A:We offer a range of surface treatments to enhance durability, appearance, and functionality, including:

Anodizing (clear or colored)

Electroless nickel plating

Chrome plating

Powder coating

Polishing, sandblasting, or bead blasting

Q:How do you ensure the quality of your milled parts?

A:We implement a rigorous quality control process, including:

Dimensional inspections: Using advanced measurement tools like CMMs.

Material verification: Ensuring raw materials meet industry standards.

Functional testing: For critical performance requirements.