High-quality turning CNC machining parts services

Product Overview

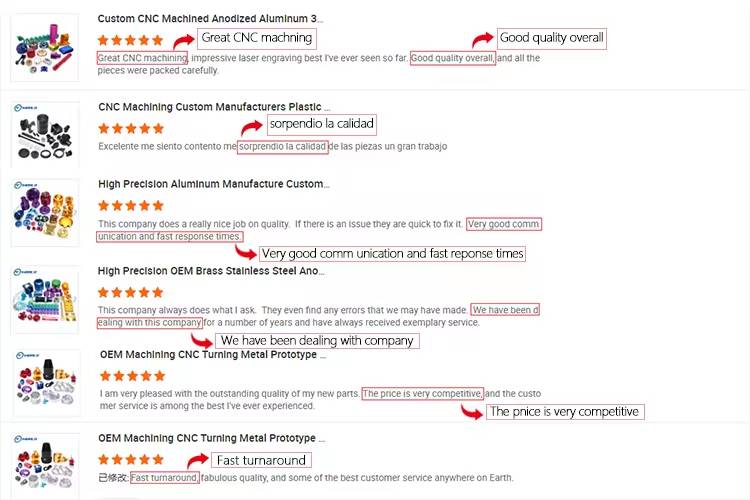

In today’s competitive manufacturing landscape, turning CNC machining parts service stands out as an essential solution for businesses seeking high-precision components with fast turnaround times. Whether you need parts for the automotive, aerospace, medical, or industrial sectors, turning CNC machining ensures exceptional accuracy, durability, and customization for your unique project needs.

This article highlights the advantages of our turning CNC machining parts service, how it benefits various industries, and why choosing a trusted manufacturer can make all the difference.

What Is Turning CNC Machining?

Turning CNC machining is a subtractive manufacturing process that involves the use of a lathe or similar equipment to rotate a workpiece while a cutting tool removes material. This process is ideal for creating cylindrical parts, including shafts, spindles, pins, bushings, and other precision components.

Using advanced CNC (Computer Numerical Control) technology, turning ensures that parts are produced with extreme precision and repeatability. Whether you require tight tolerances or intricate designs, CNC turning delivers parts that meet the most stringent specifications.

Benefits of Our Turning CNC Machining Parts Service

1.Exceptional Precision

Our CNC turning services are designed to meet your exact specifications, with tolerances as tight as ±0.005mm. This precision is vital for industries such as medical devices and aerospace, where accuracy directly impacts performance.

2.Customizable Designs

From simple geometries to complex, multi-functional designs, we offer comprehensive customization options. This ensures that your parts are perfectly tailored to your project’s unique requirements.

3.Wide Range of Materials

We work with a variety of materials, including aluminum, stainless steel, brass, copper, plastics, and more. Each material is carefully selected to meet the strength, weight, and durability needs of your application.

4.Cost Efficiency

CNC turning is highly efficient, minimizing material waste and production time. This makes it a cost-effective solution for both prototyping and large-scale production.

5.Durable Surface Finishes

We provide a range of surface finishes, such as anodizing, polishing, black oxide, and powder coating, to enhance durability and aesthetics.

Quick Turnaround Times

With our advanced machinery and streamlined production processes, we ensure fast lead times without compromising on quality.

Industries That Benefit from CNC Turning Services

1.Automotive

CNC-turned parts like gear shafts, axles, and engine components are critical for the automotive industry, where performance and durability are paramount.

2.Aerospace

The aerospace industry relies on high-precision components like connectors, bushings, and fasteners. CNC turning ensures parts can withstand extreme conditions while maintaining lightweight properties.

3.Medical Devices

In the medical field, turned components such as surgical instruments, implant parts, and diagnostic equipment must meet stringent quality standards. Our service delivers the precision and reliability required for these critical applications.

4.Industrial Equipment

For industrial machinery, we produce parts like spindles, valve components, and rollers that require high strength and wear resistance.

5.Electronics

CNC turning is used to manufacture small yet intricate components like connectors, heat sinks, and housings for consumer electronics.

Applications of CNC Turning Machined Parts

Our turning CNC machining parts service can be used for:

- Hydraulic and pneumatic components

- Precision shafts and spindles

- Threaded fasteners

- Custom bushings and bearings

- Medical implants and surgical tools

- Electrical connectors and housings

Partner with Us for Your CNC Turning Needs

When you choose our turning CNC machining parts service, you’re investing in superior craftsmanship, cutting-edge technology, and a commitment to customer satisfaction. We pride ourselves on delivering parts that not only meet but exceed industry standards.

Q:What services do you provide for CNC turning machining?

A:We offer comprehensive CNC turning machining services, including:

Custom part production: Manufacturing parts to your exact specifications.

Prototyping: Creating samples for design validation.

High-volume production: Scalable manufacturing for large orders.

Material selection: Expertise in machining various metals and plastics.

Surface finishing: Options like anodizing, plating, polishing, and powder coating.

Q:What materials do you work with for CNC turning?

A:We machine a wide range of materials to meet diverse industry needs, including:

Metals: Aluminum, stainless steel, brass, copper, titanium, and alloy steel.

Plastics: ABS, nylon, POM (Delrin), polycarbonate, and more.

Exotic materials: Tungsten, Inconel, and magnesium for specialized applications.

Q:How precise are your CNC turning services?

A:Our advanced CNC machines deliver exceptional precision with tolerances as tight as ±0.005mm, ensuring accuracy for even the most complex designs.

Q:What is the maximum size of parts you can produce?

A:We can handle parts with diameters up to 500mm and lengths up to 1,000mm, depending on the material and design requirements.

Q:Do you offer secondary processes or finishes?

A:Yes, we provide a range of secondary processes to enhance the functionality and appearance of your parts, including:

Anodizing (colored or clear)

Electroplating (nickel, zinc, or chrome)

Polishing and sandblasting

Heat treatment for strength and durability

Q:What is your typical production timeline?

A:Our production timelines vary based on order size and complexity:

Prototyping: 7-10 business days

Mass production: 2-4 weeks