Metal Parts for Industrial Robotics

Introduction

In the rapidly advancing field of industrial robotics, the importance of high-quality metal parts cannot be overstated. These components are crucial for ensuring efficiency, durability, and precision in robotic applications. In this article, we will explore the various types of metal parts used in industrial robotics, their benefits, and how they contribute to the evolution of automation.

Understanding Metal Parts in Robotics

Metal parts are fundamental to the structure and function of industrial robots. They are typically made from materials such as steel, aluminum, and titanium, each offering unique properties that enhance robotic performance.

· Steel: Known for its strength and durability, steel is commonly used in heavy-duty applications where structural integrity is critical.

· Aluminum: Lightweight and corrosion-resistant, aluminum parts are ideal for applications where weight reduction is essential without compromising strength.

· Titanium: Although more expensive, titanium parts offer exceptional strength-to-weight ratios and are used in specialized applications.

Key Metal Parts for Industrial Robotics

1.Frames and Chassis

The backbone of any robotic system, metal frames provide the necessary support and stability. They are designed to withstand the rigors of industrial environments.

2.Joints and Connectors

Metal joints facilitate movement and flexibility in robotic arms. High-quality metal connectors ensure precision in operation and longevity in performance.

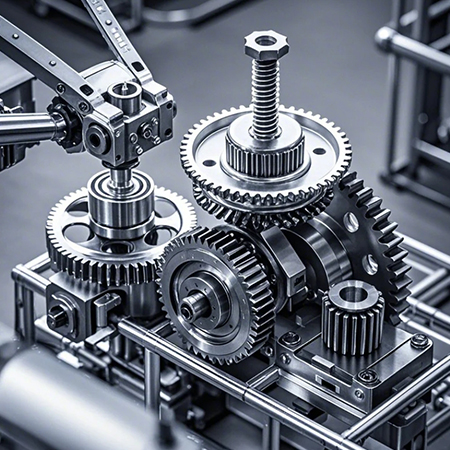

3.Gears and Drive Components

Metal gears are vital for transferring motion and power within a robot. Their durability is essential for maintaining operational efficiency over time.

4.End Effectors

Often made of metal, end effectors (or grippers) are critical for performing tasks. They must be robust yet precise to handle various materials in industrial settings.

Benefits of Metal Parts in Industrial Robotics

· Durability: Metal parts are less prone to wear and tear, ensuring a longer lifespan for robotic systems.

· Precision: High-quality metal components enhance the accuracy of robotic movements, leading to better performance in manufacturing processes.

· Customization: Many manufacturers offer tailored solutions, allowing businesses to customize metal parts to fit specific robotic applications.

As a trusted precision CNC machining parts factory, we are committed to delivering exceptional products that meet the evolving demands of modern manufacturing. Our focus on quality, precision, and customer satisfaction sets us apart in the industry. Contact us today to learn more about our precision CNC machining services and discover how we can help elevate your manufacturing processes!

Call to Action

If you’re interested in sourcing high-quality metal parts for your industrial robotics applications, contact us today! Our expertise in manufacturing durable and precise components will help you achieve your automation goals.

Q:What’s your business scope?

A: OEM Service. Our business scope are CNC lathe processed, turning,stamping,etc.

Q.How to contact us ?

A:You can send inquiry of our products,it will be replied within 6 hours;And you can contact dirrectly with us through TM or WhatsApp, Skype as you like.

Q.What information should I give to you for inquiry?

A:If you have drawings or samples,pls feel free to send us,and tell us your special requirements such as material, tolerance, surface treatments and the amount you need,ect .

Q.What about the delivery day?

A: The delivery date is about 10-15 days after receipt of payment.

Q.What about the payment terms?

A: Generally EXW OR FOB Shenzhen 100% T/T in advance,and we can also consult accroding to your requirement.