News

-

The Ultimate Double Ended M1 Bolt with Built-In Nut for Seamless Assembly

The miniaturization of electronics and medical devices has increased demand for reliable M1-sized fasteners. Traditional solutions require separate nuts and washers, complicating assembly in spaces under 5mm³. A 2025 ASME survey noted that 34% of field failures in wearables stem from fastener loo...Read more -

The Precision Machined Parts in Your Doors, Windows, and Even Skateboards

From high-security door locks to smooth-rolling skateboards, precision machined parts play an often-overlooked role in product performance and user experience. The global market for such components exceeded $12 billion in 2024, driven by demand for higher reliability and customization (Global Mac...Read more -

Manufacturers will achieve full spectrum finishing in 2025: anodizing and electroplating

Precision is no longer enough in today’s manufacturing landscape. In 2025, the competitive edge comes from CNC machining with anodizing and plating options — a game-changing combination that’s giving manufacturers total control over performance, appearance, and durability in one streamlined...Read more -

CNC Thread Milling for Custom Thread Profiles Revolutionizes Precision Manufacturing in 2025

In a year dominated by rapid design changes and tighter tolerances, CNC thread milling for custom thread profiles has emerged as one of 2025’s biggest manufacturing game-changers. From aerospace to medical to energy sectors, engineers are ditching traditional tapping methods in favor of precision...Read more -

Capacitive Sensor Supplier: Key Insights and Trends for 2025

As the demand for smart electronics, industrial automation, and IoT devices grows, capacitive sensors have become essential components in modern technology. Choosing the right capacitive sensor supplier is crucial for manufacturers seeking reliability, precision, and competitive pricing. This art...Read more -

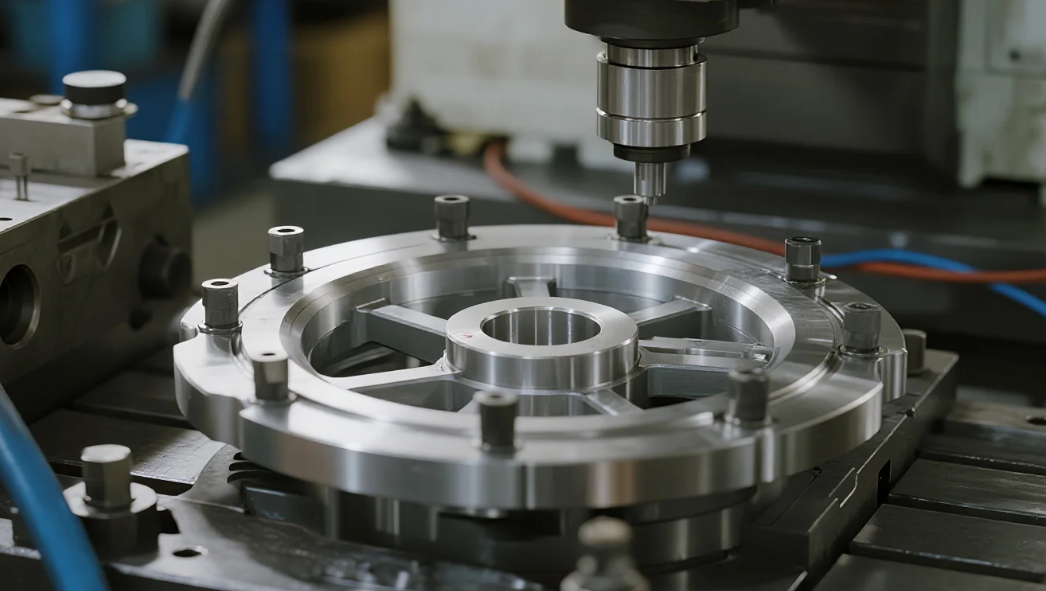

CNC Machining Parts Factory: Latest Trends and Insights in Precision Manufacturing

In today’s fast-paced manufacturing industry, CNC machining parts factories play a pivotal role in producing high-precision components for sectors ranging from automotive and aerospace to medical devices. As demand for faster, more accurate, and cost-effective production grows, understanding the ...Read more -

How to Prevent Aluminum Alloy Warping in CNC Milling with Smart Fixturing

The growing demand for thin-walled aluminum components (e.g., aircraft structural parts) has intensified warping challenges in CNC milling. Current solutions relying on passive fixturing or post-process correction incur 12-18% scrap rates in aerospace applications (Bai et al., 2023). This study a...Read more -

How to Choose a CNC Router vs. Mill for Your First Prototype Shop

The proliferation of low-cost CNC systems (Market Research Future, 2025) has complicated equipment selection for nascent prototype shops. While prior studies (Smith et al., 2023) compared industrial-grade machines, this work addresses the gap in benchmarking benchtop systems under $50,000. Key re...Read more -

Five Key Processes for Improving CNC Turning Yields: Tools, Fixtures, Cooling, and In-Line Inspection

When customers place large-volume orders for precision CNC turned parts, the first question they often ask is: “Can you guarantee both high yield and consistent quality?” From our own production experience, we know that even a 2–3% improvement in yield can mean saving thousands of dollars in mate...Read more -

17-4PH vs. 304/316: A Practical Guide to Material Selection and Heat Treatment for Aerospace-Grade Parts

1 Research Method 1.1 Experimental Design The investigation was designed to provide reproducible comparison between precipitation-hardening and austenitic stainless steels. Three materials—17-4PH, 304, and 316—were procured from certified aerospace suppliers, each in rod form with identical diame...Read more -

Demand for Titanium Alloys in the Medical and Aviation Sector Continues to Grow

Why Titanium Alloys Are in High Demand If you’ve been sourcing raw materials or finished parts in recent years, you’ve likely noticed one clear trend: titanium alloys are becoming harder to ignore. From orthopedic implants to aircraft turbine blades, titanium is no longer a niche material—it’s ra...Read more -

Measured medical part data: ±0.005mm tolerance maintained

When it comes to medical devices, precision is not just a standard—it’s a matter of safety. In our factory, we recently completed a machining project where medical parts were measured with a maintained tolerance of ±0.005mm. This benchmark didn’t come easily; it required strict process control, r...Read more