In a rapidly evolving global market, the machine tool equipment industry is spearheading a transformative movement toward innovation, efficiency, and sustainability. With growing demands for high-precision manufacturing and the integration of smart technologies, the sector is poised to redefine quality productivity like never before.

As industries like automotive, aerospace, healthcare, and electronics seek advanced manufacturing solutions, machine tool equipment is evolving to meet these demands with cutting-edge designs, enhanced capabilities, and greater reliability.

Riding the Wave of Technological Innovation

The machine tool equipment industry has always been the backbone of manufacturing, and recent advancements are accelerating its progress. Key trends driving the transformation include:

1.Smart Manufacturing: The integration of IoT, AI, and big data analytics is enabling real-time monitoring and predictive maintenance, minimizing downtime and maximizing output.

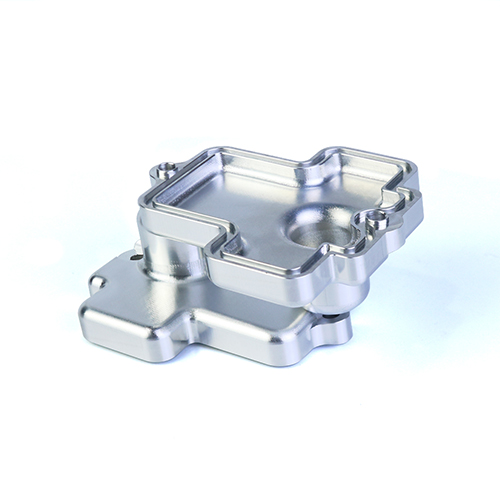

2.Precision Engineering: New machine tools offer unparalleled accuracy, catering to industries where even micrometer-level deviations can be critical.

3.Sustainability Focus: Eco-friendly designs and energy-efficient machinery are addressing environmental concerns while reducing operational costs.

4.Customization Capabilities: Flexible manufacturing solutions are empowering businesses to meet diverse customer needs with speed and efficiency.

Boosting Quality Productivity in Key Sectors

The impact of modern machine tool equipment extends across multiple industries, transforming production lines and enhancing productivity:

●Automotive: High-performance machining centers are enabling faster production of complex components like engine blocks and transmission systems.

●Aerospace: Advanced CNC machines are delivering precision for intricate aerospace parts, ensuring safety and performance.

●Medical Devices: Innovations in machine tooling are critical for producing high-quality implants, surgical instruments, and diagnostic equipment.

●Electronics: Miniaturization and precision machining are supporting the production of micro-components for cutting-edge electronics.

Industry Leaders Paving the Way

Prominent players in the machine tool equipment industry are setting benchmarks for quality and productivity:

●DMG Mori, Mazak, and Haas Automation are revolutionizing CNC machining with faster, smarter, and more reliable equipment.

●FANUC and Siemens are advancing automation and control systems to integrate seamlessly with modern manufacturing processes.

●Emerging startups are focusing on niche solutions like additive manufacturing and hybrid machine tools, further diversifying the landscape.

What’s Next for the Machine Tool Industry?

The industry’s trajectory points toward more intelligent and sustainable manufacturing practices. Key developments to watch include:

●AI-Powered Machining: Predictive algorithms will optimize cutting paths, tool wear, and overall efficiency.

●Hybrid Solutions: Machines combining additive and subtractive manufacturing methods will offer unparalleled flexibility.

●Global Collaboration: Partnerships across borders will drive innovation and standardization, benefiting manufacturers worldwide.

The Road Ahead: A New Era of Quality Productivity

The machine tool equipment industry is not just keeping pace with global manufacturing demands—it’s leading the charge toward a future defined by new quality productivity. By embracing cutting-edge technologies, sustainable practices, and customer-centric solutions, the sector is poised to transform how goods are made.

As businesses seek to enhance competitiveness in today’s dynamic market, the role of advanced machine tools will only become more pivotal. Investing in innovation today ensures a more productive and profitable tomorrow.

Post time: Dec-16-2024