In the ever-evolving world of manufacturing, turning CNC machining parts are leading a revolution. With industries demanding greater precision, efficiency, and customization, CNC (Computer Numerical Control) technology has become indispensable, particularly in turning operations. These meticulously crafted parts are powering everything from automotive engines to aerospace components, making turning CNC machining parts a cornerstone of modern industrial progress.

But why are these parts so essential, and how are they redefining manufacturing? Let’s explore how turning CNC machining is setting new benchmarks for precision, performance, and production efficiency.

What Are Turning CNC Machining Parts?

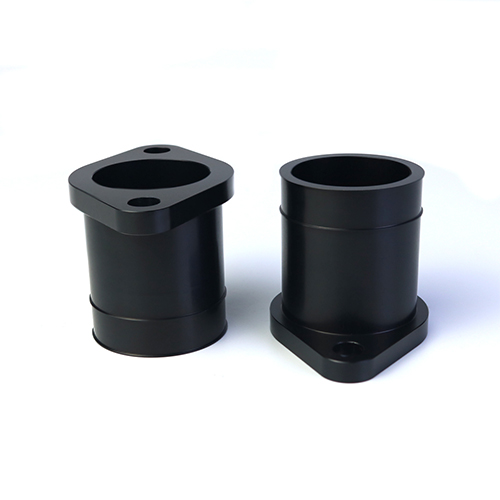

At its core, turning CNC machining involves removing material from a rotating workpiece to create precise cylindrical shapes. This process is executed using highly advanced CNC lathes, which are programmed to produce parts with exceptional accuracy and consistency.

Typical examples of turning CNC machining parts include shafts, bushings, spindles, screws, and flanges, all of which require high precision to ensure seamless performance in their respective applications.

Unlike traditional turning methods, CNC machines can produce parts with micron-level tolerances, making them ideal for industries where even the smallest deviation can compromise performance, such as aerospace, medical devices, automotive, and electronics.

Why Turning CNC Machining Parts Are Transformative

1. Unparalleled Precision

Precision is the hallmark of turning CNC machining. Modern CNC lathes are equipped with cutting-edge software and tools that enable manufacturers to produce parts with incredible accuracy.

For example, aerospace components like turbine shafts or medical implants like bone screws require perfect geometry to perform as intended. CNC turning ensures these components meet stringent quality standards, eliminating the risks associated with manual errors.

2. Increased Production Efficiency

CNC turning machines operate at high speeds while maintaining consistency across large production runs. Unlike manual lathes, which require constant human supervision, CNC lathes can run autonomously, dramatically reducing production time and labor costs.

For industries producing large volumes of turned parts, such as automotive or industrial machinery, CNC technology allows for faster, more cost-effective manufacturing without sacrificing quality.

3. Enhanced Customization

The flexibility of CNC machining allows manufacturers to produce custom parts tailored to specific applications. With advanced CAD/CAM software, engineers can design complex geometries and translate them directly into CNC programs.

Whether it’s a one-off prototype or a batch of custom parts for high-performance engines, CNC turning offers unparalleled design freedom. This is especially valuable in sectors like motorsports and luxury goods, where unique, high-performance parts are in high demand.

4. Superior Material Compatibility

CNC turning machines can handle a wide range of materials, from traditional metals like aluminum, steel, and brass, to advanced alloys and composites like titanium and carbon fiber.

This versatility enables manufacturers to meet the diverse needs of industries that require materials with specific properties, such as lightweight aerospace parts or corrosion-resistant medical implants.

Applications Driving Demand for Turning CNC Machining Parts

1.Automotive Industry

Turning CNC machining parts are vital in the automotive sector, producing critical components such as engine pistons, gear shafts, and steering components. The precision and durability of CNC-turned parts ensure optimal vehicle performance, efficiency, and safety.

2.Aerospace Engineering

In aerospace, there is no room for error. CNC-turned parts like aircraft fasteners, landing gear components, and turbine shafts are manufactured to exact specifications to meet the rigorous demands of flight environments.

3.Medical Devices

The medical industry relies heavily on CNC machining for producing surgical tools, implants, and prosthetics. Turning CNC machining ensures these parts are not only precise but also biocompatible and safe for use in sensitive applications.

4.Electronics

From tiny connectors to heat sinks, CNC turning plays a crucial role in the electronics industry. The ability to work with delicate materials and produce small, intricate parts has made CNC turning indispensable in this field.

Technological Advancements in CNC Turning

The field of CNC turning is evolving rapidly, with innovations that enhance speed, accuracy, and functionality:

1. Multi-Axis CNC Lathes

Modern CNC lathes now feature multi-axis capabilities, enabling complex geometries to be produced in a single setup. This eliminates the need for secondary operations, reducing production time and costs.

2. IoT Integration

Smart CNC machines equipped with IoT sensors allow real-time monitoring of machining operations, ensuring quality control and predictive maintenance.

3. Advanced Cutting Tools

The development of high-performance cutting tools, such as diamond-tipped or coated carbide inserts, has improved machining efficiency and extended tool life, even when working with tough materials like titanium or Inconel.

The Future of Turning CNC Machining Parts

As industries continue to demand higher precision and efficiency, turning CNC machining will play an increasingly critical role. The integration of artificial intelligence and automation is poised to make CNC turning machines even more intelligent and capable, allowing for greater customization and faster production cycles.

Moreover, with the push toward sustainability, CNC machining is adopting eco-friendly practices, such as reducing material waste through optimized machining processes and utilizing recyclable materials.

Conclusion: Turning CNC Machining Parts as a Catalyst for Progress

The rise of turning CNC machining parts represents a significant leap forward for manufacturing industries. By combining precision, efficiency, and versatility, these parts are driving innovation across a wide range of applications, from transportation and healthcare to technology and defense.

As CNC technology continues to advance, the possibilities for turning CNC machining parts are virtually limitless. For manufacturers aiming to stay competitive in a rapidly changing world, investing in cutting-edge CNC turning capabilities is not just an option—it’s a necessity.

Whether it’s powering next-generation vehicles, enabling life-saving medical devices, or creating the electronics of the future, turning CNC machining parts are at the forefront of precision manufacturing in the 21st century.

Post time: Jan-06-2025