PFTH17 1-axis Ball Screw Drive Linear guide rail comparison CNC slider module

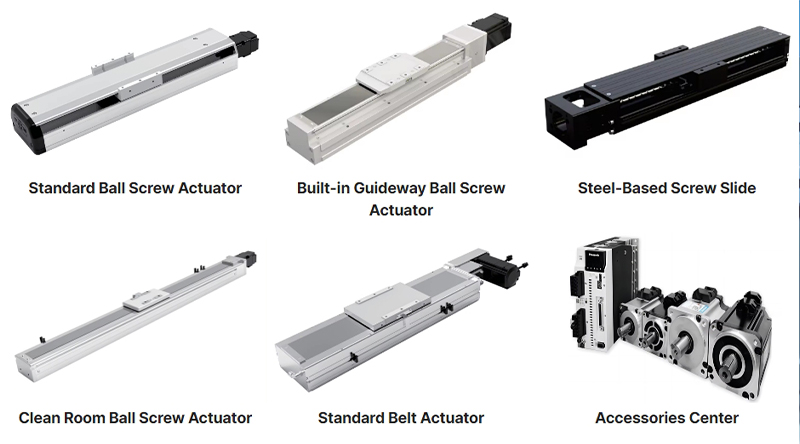

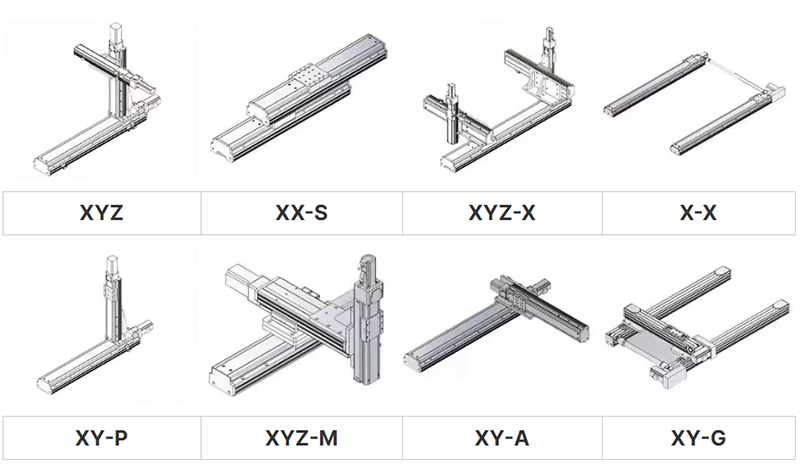

Enter the 750W CNC slider module, equipped with 1-axis Ball Screw Drive Linear guide rail technology. With impressive specifications ranging from 250-2000mm/s speed, 320-2563N stroke, and a stroke pitch spanning 50-1250mm, this revolutionary module stands poised to transform machining processes. In this article, we delve into the capabilities of the 1-axis Ball Screw Drive Linear guide rail CNC slider module and compare it with traditional linear guide rails, showcasing its potential to redefine industry standards.

Unveiling the 1-axis Ball Screw Drive Linear Guide Rail CNC Slider Module

At the heart of precision machining lies the CNC slider module, a critical component that facilitates precise movement and positioning of machine tools. The incorporation of 1-axis Ball Screw Drive Linear guide rail technology elevates this module to new heights of performance. With a power output of 750W, it offers unparalleled speed and precision, making it ideal for a wide range of machining applications.

Key Specifications and Performance Metrics

1.Speed Range (250-2000mm/s): The ability to operate within this extensive speed range allows for optimal adaptability to varying machining requirements. Whether it's rapid traversing or fine finishing, the CNC slider module delivers consistent performance across different speed settings.

2.Stroke and Stroke Pitch (320-2563N, 50-1250mm): The impressive stroke capabilities enable the module to cover a wide range of motion, accommodating diverse machining tasks with ease. Additionally, the adjustable stroke pitch enhances flexibility, allowing for precise customization according to specific application needs.

Advantages over Traditional Linear Guide Rails

1.Enhanced Precision: The incorporation of Ball Screw Drive technology ensures smoother and more precise movement compared to conventional linear guide rails, resulting in superior machining accuracy and surface finish.

2.Higher Speeds: With the ability to achieve speeds of up to 2000mm/s, the CNC slider module offers significant productivity gains compared to traditional linear guide rails, enabling faster machining cycles and reduced lead times.

3.Greater Load Capacity: The robust design of the module allows for higher load capacities, making it suitable for machining heavy-duty workpieces with ease and stability.

Applications and Industry Impact

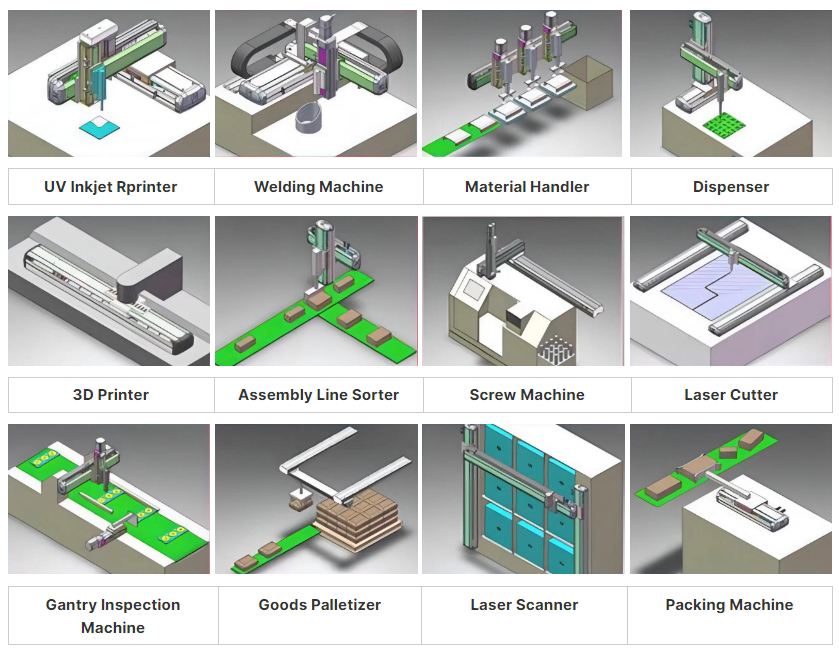

The versatility and performance of the 1-axis Ball Screw Drive Linear guide rail CNC slider module make it indispensable across various industries, including automotive, aerospace, electronics, and manufacturing. From precision milling and drilling to high-speed machining and engraving, its capabilities enable manufacturers to meet the stringent quality and productivity demands of modern production environments.

Q:How long does customization take?

A: Customization of linear guideways requires determining the size and specifications based on the requirements, which typically takes around 1-2 weeks for production and delivery after placing the order.

Q. What technical parameters and requirements should be provided?

Ar: We require buyers to provide the three-dimensional dimensions of the guideway such as length, width, and height, along with load capacity and other relevant details to ensure accurate customization.

Q. Can free samples be provided?

A: Usually, we can provide samples at the buyer's expense for the sample fee and shipping fee, which will be refunded upon placing the order in the future.

Q. Can on-site installation and debugging be performed?

A: If a buyer requires on-site installation and debugging, additional fees will apply, and arrangements need to be discussed between the buyer and the seller.

Q. About price

A: We determine the price according to the specific requirements and customization fees of the order, please contact our customer service for specific pricing after confirming the order.