Turbine manufacturing OEM CNC machining workshop for equipment

Product Overview

In the high-demand world of industrial power generation, precision and reliability are essential for achieving operational efficiency. Steam turbines, a vital component in energy production, require parts and components of the highest quality. OEM CNC machining workshops specializing in manufacturing steam turbines offer the advanced capabilities necessary to deliver precision-engineered components that meet exacting industry standards.

What Is an OEM CNC Machining Workshop?

An OEM CNC machining workshop is a specialized facility equipped with advanced CNC (Computer Numerical Control) machines designed to produce custom parts for original equipment manufacturers (OEMs). When it comes to manufacturing steam turbines, these workshops play a critical role in crafting components with precision, ensuring the seamless integration and performance of the turbine system.

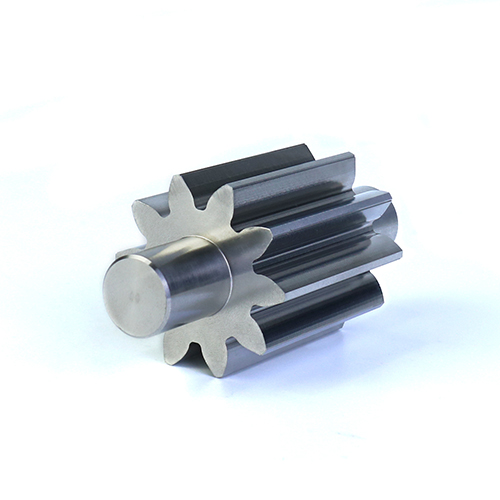

The components of a steam turbine, such as rotors, blades, casings, and seals, require meticulous design and manufacturing processes to handle the extreme pressures and temperatures of steam generation. CNC machining ensures that each part meets tight tolerances, providing optimal performance and longevity.

Key Components Manufactured in OEM CNC Machining Workshops

An OEM CNC machining workshop manufacturing steam turbines produces a wide range of critical components, including:

●Rotors: The central shaft of the turbine that drives the energy conversion process.

●Blades: Precisely engineered blades that interact with steam to generate rotational energy.

●Casings: Durable housings that protect the turbine’s internal components.

●Seals: High-precision seals that prevent steam leakage and improve efficiency.

●Bearings and Shafts: Components designed to support and stabilize the turbine’s moving parts.

Advanced Capabilities of CNC Machining Workshops

CNC machining workshops dedicated to steam turbine manufacturing offer a range of advanced capabilities:

●5-Axis CNC Machining: Enables the creation of complex geometries required for turbine blades and rotors.

●High-Speed Machining: Reduces production times without compromising precision.

●CAD/CAM Integration: Ensures seamless design-to-production workflows for custom turbine components.

●Surface Treatments: Enhances durability with processes like polishing, anodizing, and coating.

Industries Benefiting from OEM CNC Machining for Steam Turbines

Steam turbines are essential in numerous industries, including:

●Power Generation: Energy plants rely on steam turbines for electricity production.

●Petrochemical: Refineries and processing plants use turbines for efficient steam-to-energy conversion.

●Marine: Ships equipped with steam turbines benefit from reliable propulsion systems.

●Industrial Manufacturing: Steam turbines power machinery and processes in heavy industries.

Choosing the Right OEM CNC Machining Workshop

When selecting a machining workshop for manufacturing steam turbines, consider the following factors:

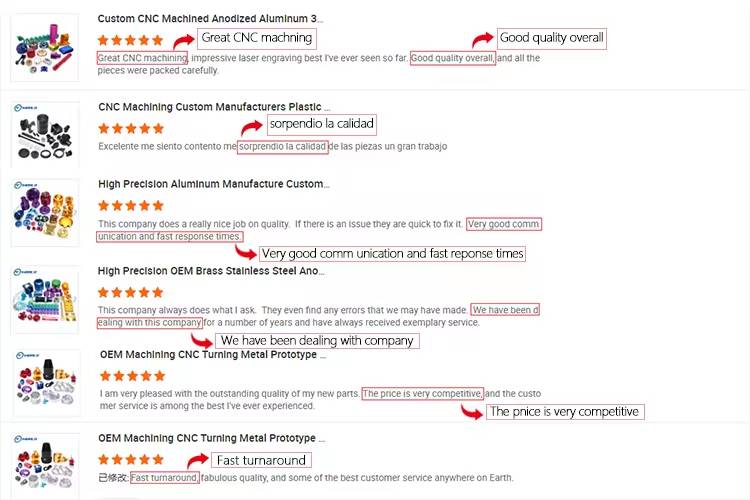

●Experience and Expertise: Choose a workshop with a proven track record in producing high-precision turbine components.

●State-of-the-Art Equipment: Ensure the facility is equipped with advanced CNC machines and tools.

●Material Expertise: Look for expertise in machining high-performance materials used in steam turbines.

●Quality Assurance: Confirm that the workshop adheres to strict quality control processes and certifications.

●Customer Support: Reliable communication and support ensure that your project is completed on time and to your satisfaction.

Conclusion

In the high-stakes world of power generation and industrial manufacturing, precision is non-negotiable. OEM CNC machining workshops specializing in manufacturing steam turbines provide the advanced capabilities needed to produce durable, high-performance components. By partnering with a trusted workshop, you can ensure the efficiency, reliability, and longevity of your steam turbines.

If you’re looking for a reliable partner for OEM brass CNC machining parts service, we are here to deliver precision-engineered solutions that meet your exact needs. From electronics to industrial machinery, our expertise in brass machining ensures that your components are not only functional but also built to last.

Q:How do you ensure the quality of parts produced in your workshop?

A:Quality control is a top priority in our CNC machining workshop. We ensure the highest standards by:

Using advanced CNC machines that offer high precision and repeatability.

Implementing strict inspection protocols, including dimensional checks and material testing, throughout the production process.

Utilizing CAD/CAM software to simulate machining processes and ensure design accuracy before actual manufacturing.

Carrying out extensive post-machining testing, such as non-destructive testing (NDT), to detect any potential defects.

Q:What materials are typically used in steam turbine manufacturing?

A:Steam turbines require materials that can withstand extreme temperatures, pressures, and stresses. Some of the commonly used materials include:

Alloy steels – Known for their strength, toughness, and ability to withstand high temperatures. Stainless steels – Offering corrosion resistance and durability.

Nickel-based superalloys – Ideal for high-temperature, high-stress applications in turbine blades and rotors.

Titanium – Lightweight and corrosion-resistant, used in certain turbine components.

Q:What is the lead time for manufacturing steam turbine components?

A:Lead times vary depending on the complexity of the part, the material used, and the current production schedule. For most custom turbine components, the lead time typically ranges from a few weeks to several months. We work closely with our clients to provide accurate delivery timelines and ensure we meet all production deadlines.

Q:Can you provide custom designs for steam turbine components?

A:Yes, our CNC machining workshop specializes in custom manufacturing. Whether you need a specific turbine blade design, rotor modifications, or a completely unique part, we can accommodate custom designs. Our team works with your engineers to bring your vision to life while ensuring that every part meets performance and safety standards.

Q:Do you offer maintenance and repair services for steam turbine components?

A:Yes, in addition to manufacturing new components, we also offer maintenance and repair services for steam turbines. Our skilled technicians can help extend the life of your equipment by repairing damaged components or replacing worn parts. We also provide retrofitting services to update older turbine systems with modern, high-performance components.